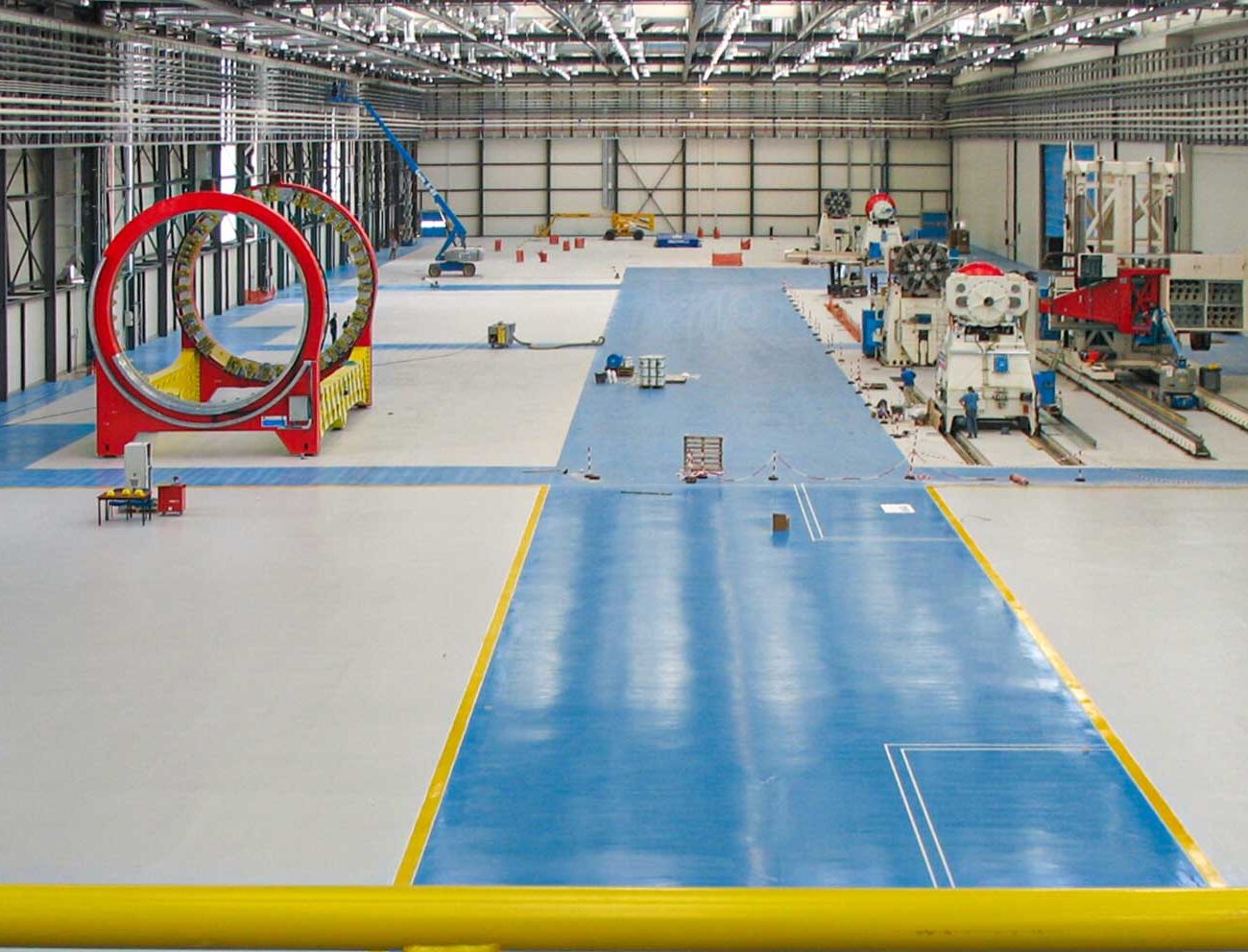

The SistemPav company in Melfi specializes in the design, construction and installation of industrial and civil flooring, resin treatments and coatings, paints, offering a high quality service and a product of guaranteed reliability over time.

Registered office: Via S. Sofia, 64 – 85025 Melfi (PZ)

Phone: +39 0972 24827

Email: info@sistempav.com